Custom Enclosure Plastic Injection Moulding Parts Electronic

Plastic Parts

Thermoplastics (Thermo plastics):

refers to plastics that melt after heating, can flow to the mold

after cooling, and then melt after heating; heating and cooling can

be used to produce reversible changes (liquid ←→solid), yes The

so-called physical change. General-purpose thermoplastics have

continuous use temperatures below 100°C. Polyethylene, polyvinyl

chloride, polypropylene, and polystyrene are also called the four

general-purpose plastics. Thermoplastic plastics are divided into

hydrocarbons, vinyls with polar genes, engineering, cellulose and

other types. It becomes soft when heated, and becomes hard when

cooled. It can be repeatedly softened and hardened and maintain a

certain shape. It is soluble in certain solvents and has the

properties of being meltable and soluble. Thermoplastics have

excellent electrical insulation, especially polytetrafluoroethylene

(PTFE), polystyrene (PS), polyethylene (PE), polypropylene (PP)

have extremely low dielectric constant and dielectric loss, so For

high frequency and high voltage insulating materials.

Thermoplastics are easy to mold and process, but have low heat

resistance and are easy to creep. The degree of creep varies with

load, environmental temperature, solvent, and humidity.

Basic parameters:

| Steel of Cavity & Core | DIN 1.2316/ DIN 1.2738/DIN 1.2344 /M300/ 718/ P20..etc |

| Steel of Mouldbase | S50C.LkM standard…etc |

| Nos of Cavity | Customized |

| Hardness of Cavity & Core | 42-45HR |

| Hardness of Wear Parts | 42-48HRC |

| Core pulling system | Motor /oil cylinder/ stripping plate, angel pin…etc |

Company introduction:

Bokda owns two manufacturing plants, and the area of new plant over

14,000 square meters. Among them, the steel structure workshop area

is more than 6,600 square meters.

At Bokda, our custom industrial molding solutions assist clients in

a variety of industries, including military industry, medical, food

processing, mining, oil and gas, waste-water management, electronic

appliances, health care & beauty etc.

Our comprehensive services:

1.Product design

We can develop new products based on your ideas, sketch, samples or

prototypes.

2.Mold analysis

This is a very important process,because we need to understand the

possibility of production in advance so as to avoid some potential

problems , such as air trap, trace, shrinkage... To save cost,

control quality and guarantee production time.

3.Prototyping

Many clients are not sure whether the products they develop can accurately

match the equipment, so many times they need to use 3D molding

technology before making molds.

4.Injection mold

We can make the injection mold with different requests, and our

mold life can reach at least 300000 shots.

5.Injection molding

We have more than 35 sets of injection machines, from dozens of tons to thousands of tons.

6. Mold storage

We'd like to store clients' molds for future production, and we

have saved more than a thousand sets of molds for previous clients.

If the mold exceeds its service life, we provide free mold repair

service to save cilents' time and cost.

Material | acrylic/pp/ABS/PC/PS/NELON |

| Color | Transparent/Semi/Panton |

| Process | Injection |

| Runner | Hot or Cool |

| Cavity | Multiple |

| Mould Time | 30-35days |

| Quality Control | ISO/TS16949:2002 and ISO14001:2004 system |

| Business Scope | Mold and parts designing and making,Parts machining,Injection

molding,CNC prototype manufacturing |

| Mould Processing | CNC EDM machine processing then assembly and trial |

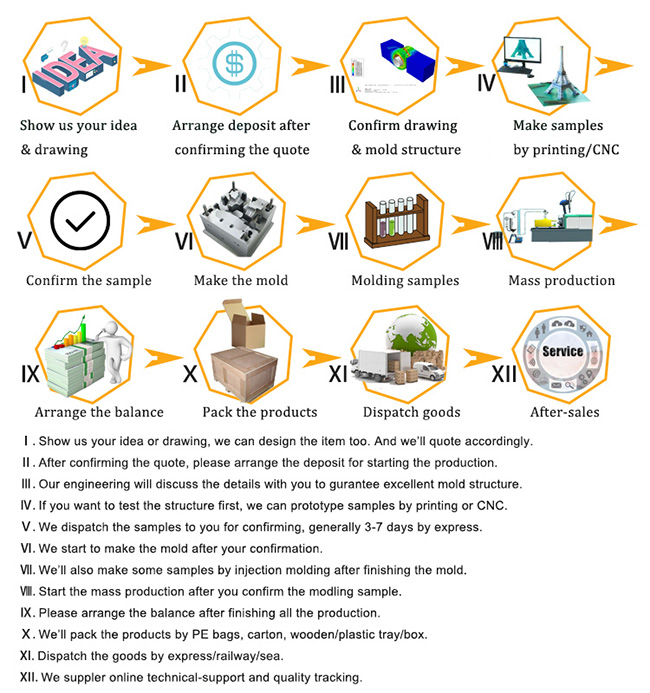

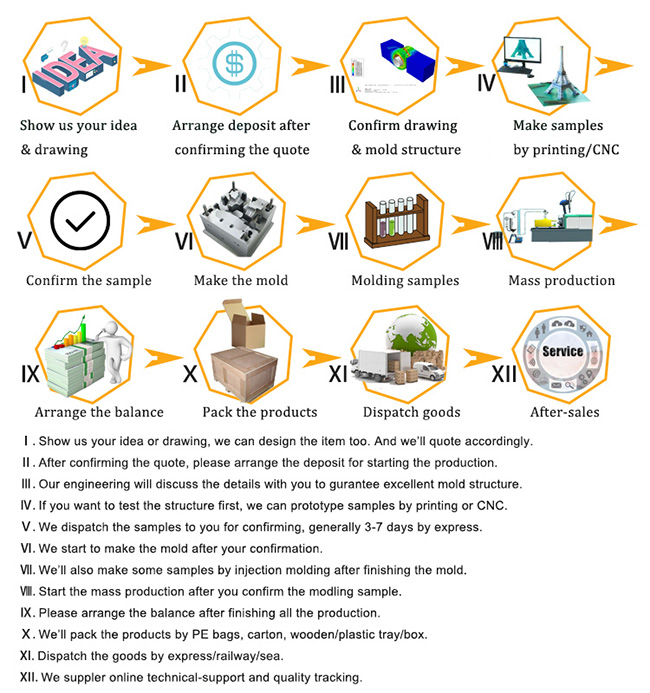

Business process:

Product pacakage: